|

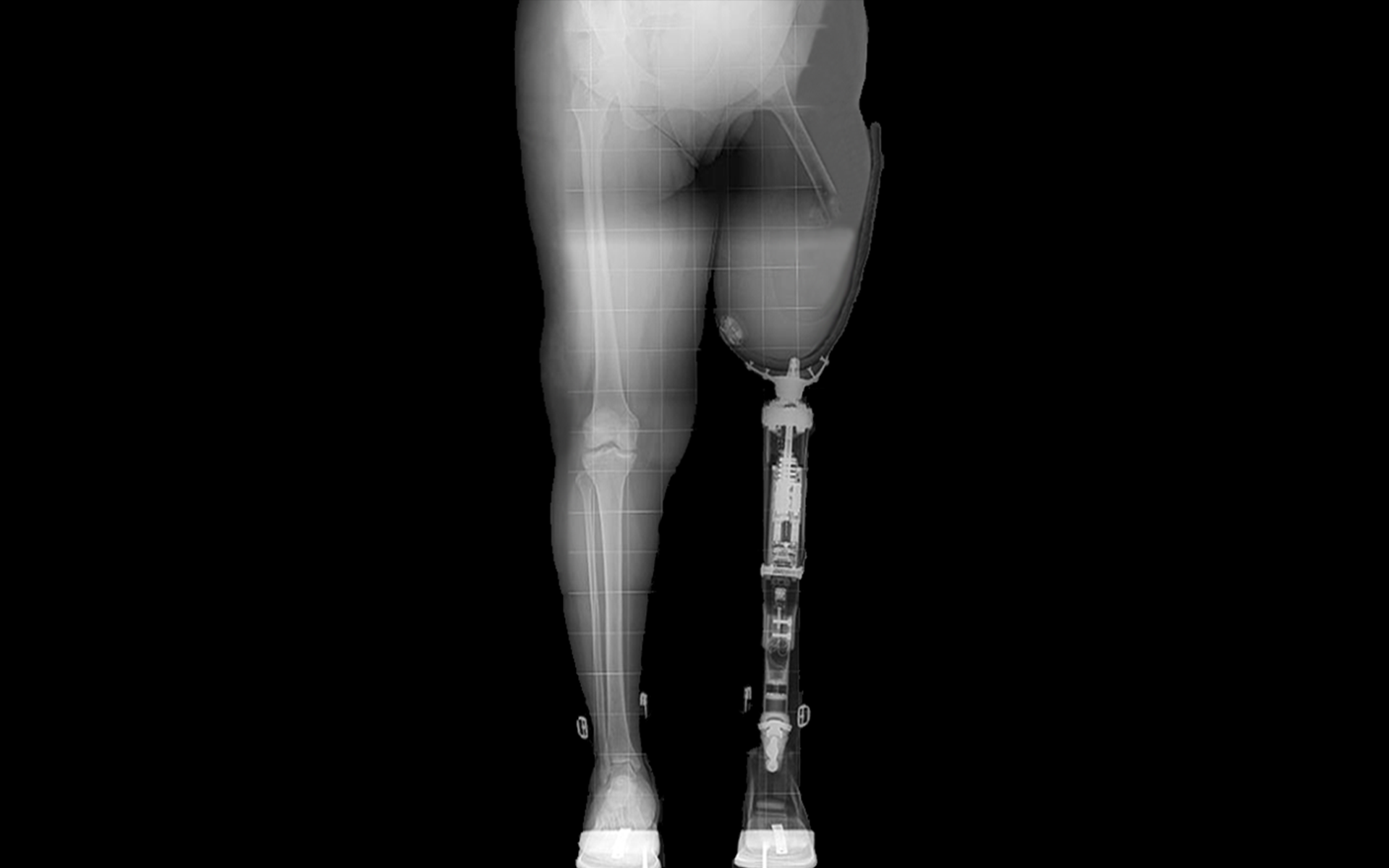

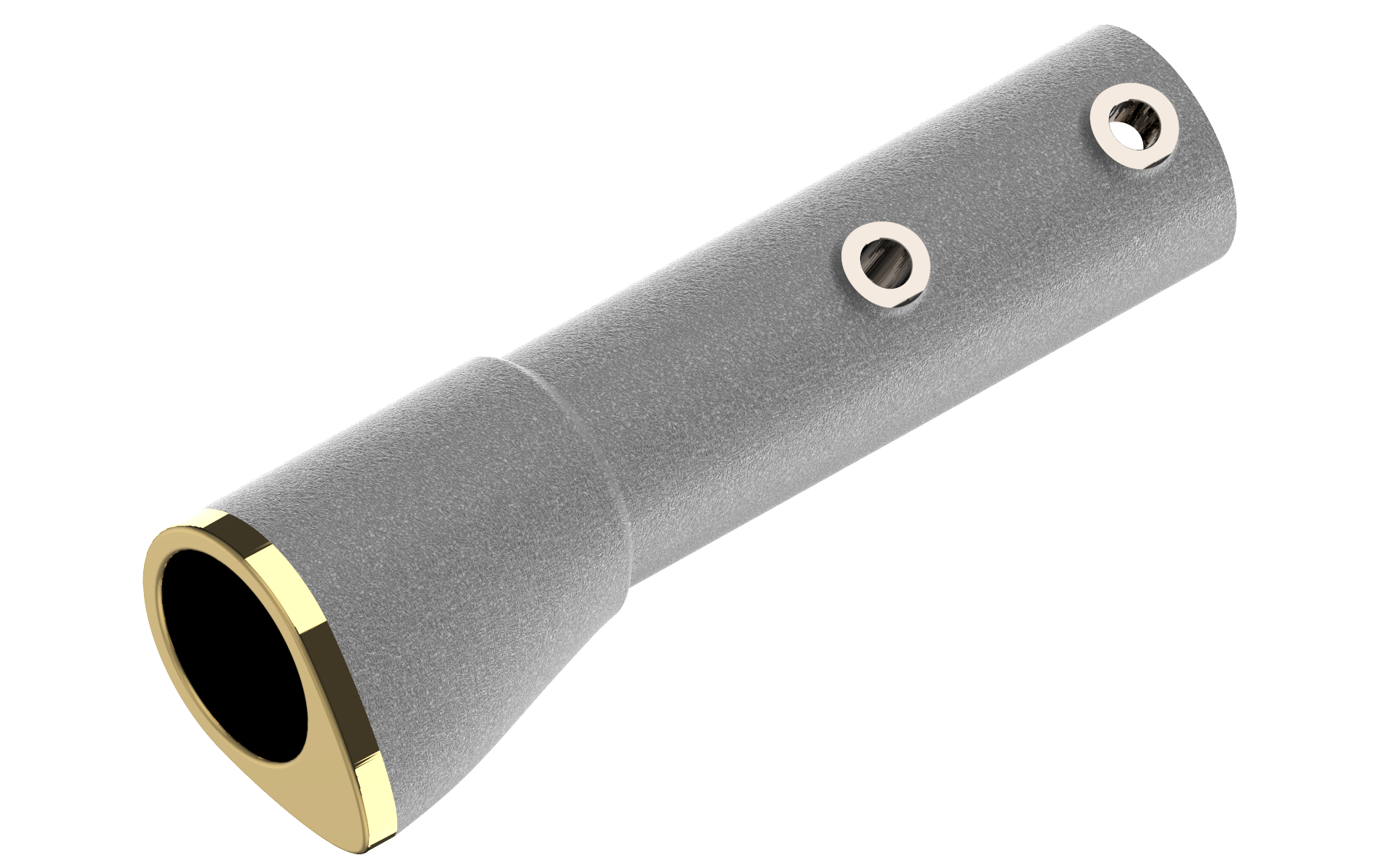

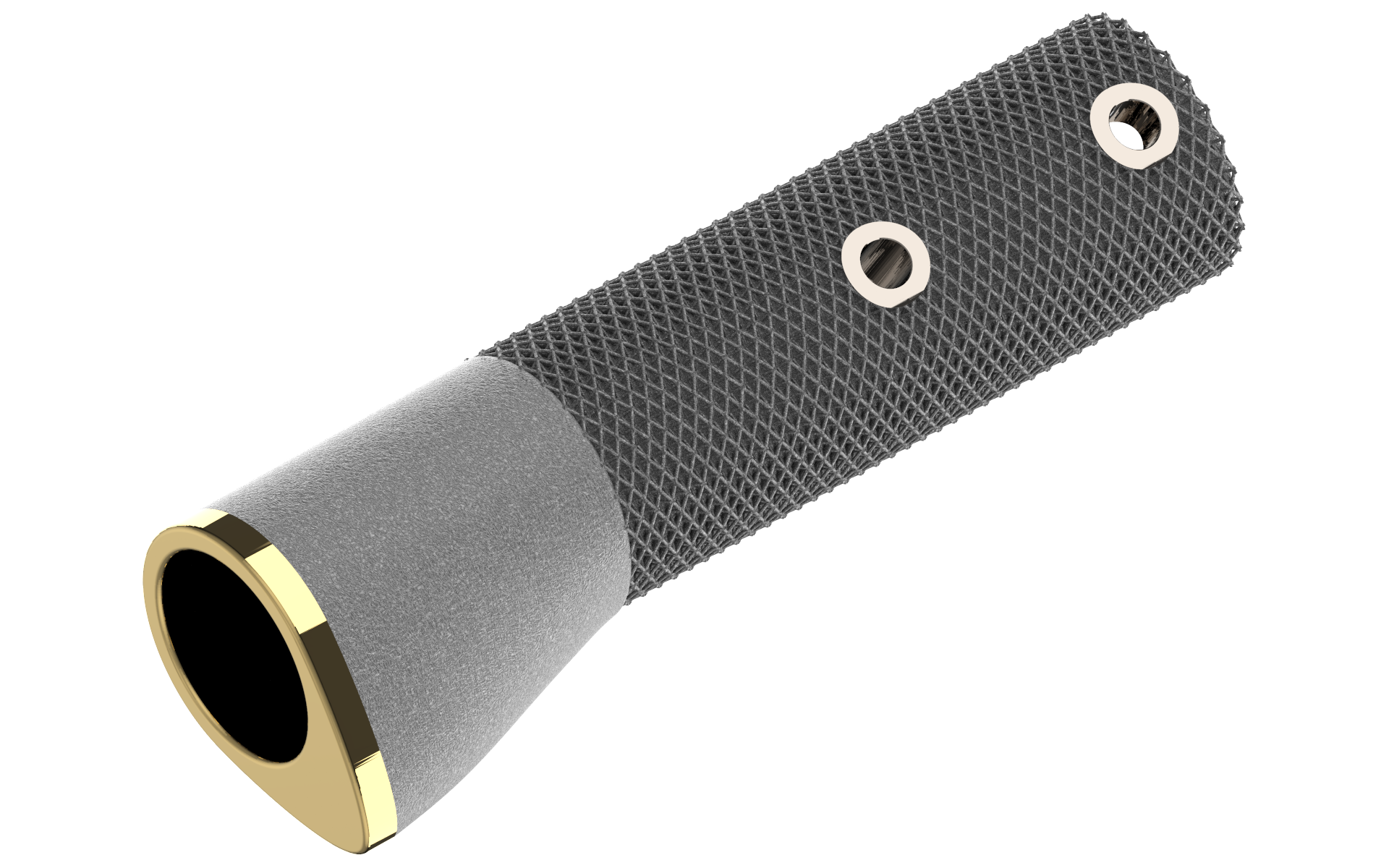

Osseointegration ImplantsConnecting to youThe intramedullary osseointegration implants are made of Titanium Aluminium Vanadium alloy (Ti6Al4V ISO5832/3). The bone contact area of the implants have a porous titanium plasma sprayed (TPS 2) coating for maximum osseointegration capacity. The average coating thickness is 350 µm ± 50 µm and 55 µm ± 15 µm roughness with 30% ± 10% porosity and >22 MPa adhesive strength or have a 3D printed surface mesh |

Today’s SocketLosing an extremity is a lifechanging event, resulting in long and heavy rehabilitation trajectories. Socket disadvantages:

|

|

|

Tibia & FemurThe anchorage of the implants is achieved through primary press fit stabilization without the use of bone cement. The devices do not contain ferromagnetic materials. As visualized the implants exists from a solid Titanium 6 Aluminum 4 Vanadium alloy core with a strong mesh structure to allow for Osseointegration |

Tibia & Femur |

|

State of the art Manufacturing

|

|